Optimum Toughness Of The Grains Brown Fused Alumina,Suite To Abrasives And Refractorie

- Brown aluminium oxide

- BFA

- Brown corundum

Short Description

Application

Brown Fused Alumina is a tough, sharp abrasives which is highly suitable for grinding metals of high tensile strength. Its thermal properties make it an excellent material for use in the manufacture of refractory products. This material is also used in other applications like blasting and surface hardening.

| Grade | Specification |

Chemical Composition(F46) |

||||

| Al2O3 | SiO2 | Fe2O3 | TiO2 | CaO | ||

| Brick Grade * | 0-1,1-3,3-5mm-8+16,-16+30,-30+60mesh,Fines | ≥95.2 | ≤1.0 | ≤0.3 | ≤3.0 | ≤0.4 |

| Castable Grade | 0-1,1-3,3-5mm-8+16,-16+30,-30+60mesh,Fines | ≥95 | ≤1.5 | ≤0.3 | ≤3.0 | ≤0.4 |

| Vitrified Grade | F12-F220 | ≥95.5 | ≤1.0 | ≤0.3 | 2.2-3.0 | ≤0.4 |

| Resin &Blasting Grade | F12-F220 | ≥95 | ≤1.5 | ≤0.3 | ≤3.0 | ≤0.4 |

| Micro Grade | P240-P1200 | ≥92-95 | ≤1.0-1.8 | ≤0.3-0.5 | ≤2.2-4.5 | - |

| F240-F1000 | ≥88-95 | ≤1.0-2.5 | ≤0.3-0.5 | ≤2.2-6.5 | - | |

| Melting point | 2050℃ | |||||

| Refractoriness | 1980℃ | |||||

| True density | 3.90ming/cm3 | |||||

| Mohs hardness | 9.00min | |||||

|

Items |

Size |

Chemical Composition (%) |

||||

|

Al2O3 |

TiO2 |

CaO |

SiO2 |

Fe2O3 |

||

|

A和A-P1 |

F4~F80 P12~P80 |

95.00~97.50 |

1.70~3.40 |

≤0.42 |

≤1.00 |

≤0.30 |

|

F90~F150 P100~P150 |

94.50~97.00 |

|||||

|

F180~F220 P180~P220 |

94.00~97.00 |

1.70~3.60 |

≤0.45 |

≤1.00 |

≤0.30 |

|

|

F230~F800 (P240~P800) |

≥93.50 |

1.70~3.80 |

≤0.45 |

≤1.20 |

≤0.30 |

|

|

F1000~F1200 (P1000~P1200) |

≥93.00 |

≤4.00 |

≤0.50 |

≤1.40 |

≤0.30 |

|

|

P1500~P2500 |

≥92.50 |

≤4.20 |

≤0.55 |

≤1.60 |

≤0.30 |

|

|

A-B和A-P2 |

F4~F80 P12~P80 |

≥94.00 |

1.50~3.80 |

≤0.45 |

≤1.20 |

≤0.30 |

|

F90~F220 P100~P220 |

≥93.00 |

1.50~4.00 |

≤0.50 |

≤1.40 |

- |

|

|

F230~F800 (P240~P800) |

≥92.50 |

≤4.20 |

≤0.60 |

≤1.60 |

- |

|

|

F1000~F1200 (P1000~P1200) |

≥92.00 |

≤4.20 |

≤0.60 |

≤1.80 |

- |

|

|

P1500~P2500 |

≥92.00 |

≤4.50 |

≤0.60 |

≤2.00 |

- |

|

|

A-S |

16~220 |

≥93.00 |

- |

- |

- |

- |

Brick/ Vitrified Grade BFA : Is produced using special grade Bauxite in controlled fusion parameters. This grade is suitable for Bricks/ Vitrified products preventing Cracks/ Fissures, Holes and Black spots in the end product.

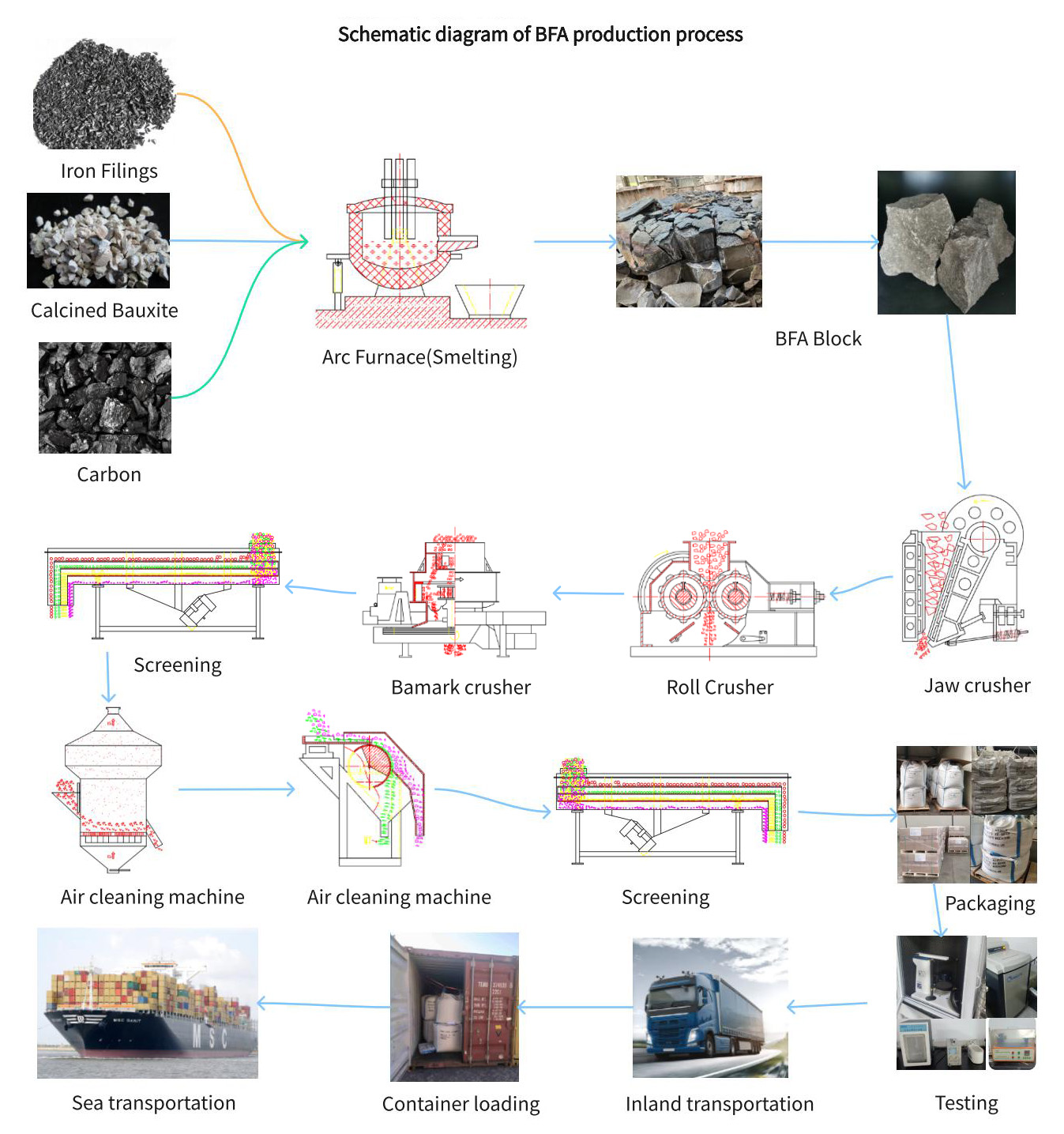

Process Of Production

Brown Fused Alumina is produced by the smelting of Calcined Bauxite in an electric arc furnace at temperatures greater than 2000°C. A slow solidification process follows the fusion, to yield blocky crystals. The melting help in removing residual sulphur and carbon , Strict control over Titania levels during the fusion process ensures optimum toughness of the grains.

Then the cooled crude is further crushed, cleaned of magnetic impurities in high intensity magnetic separators and classified into narrow size fractions to suit the end use. Dedicated lines produce products for different applications.