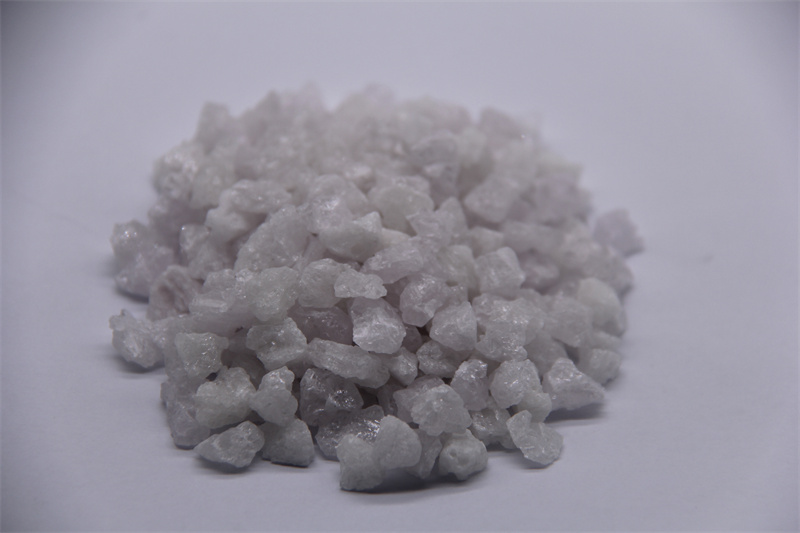

High Temperature Resistance,Large Body Density,Low Water Absorption, Small Thermal Expansion Coefficient Fused Spinel

- Magnesium aluminate spinel

- Fused magnesium aluminate spinel

- High purity fused spinel

Short Description

Process Of Production And Application

Manufactured from high purity magnesia and Bayer process alumina in large electric arc furnace. It has excellent refractory properties, and can be used to produce Bricks and Castables in areas where slag resistance is key.

Such as: Roof of EAF and basic oxygen furnace, Steel ladle, intermediate zone of cement rotary kiln, etc.

|

ITEM |

UNIT |

BRANDS |

||||

|

AM-70 |

AM-65 |

AM-85 |

AM90 |

|||

| Chemical

composition |

Al2O3 | % | 71-76 | 63-68 | 82-87 | 88-92 |

| MgO | % | 22-27 | 31-35 | 12-17 | 8-12 | |

| CaO | % | 0.65max | 0.80max | 0.50max | 0.40max | |

| Fe2O3 | % | 0.40max | 0.45max | 0.40max | 0.40max | |

| SiO2 | % | 0.40max | 0.50max | 0.40max | 0.25max | |

| NaO2 | % | 0.40max | 0.50max | 0.50max | 0.50max | |

| Bulk Density g/cm3 | 3.3min | 3.3min | 3.3min |

3.3min |

||

‘S’ ----sintered ; F-----fused ; M------magnesia; A----alumina; B----bauxite

Fused Spinel Characteristics

Product introduction:Fused magnesia-aluminum spinel is made of high-quality low-sodium alumina a high-purity light-burned magnesia powder as raw materials, and is smelted in an electric arc furnace a high temperature above 2000℃.

Product features: high temperature resistance,large body density,low water absorption, small thermal expansion coefficient,good thermal shock stability, strong corrosion resistance and slag resistance.

Compared with the sintering method to synthesize spinel, the electrofusion method has a higher calcination temperature, about 2000°C, which makes the spinel denser, has a higher volume density, and is more resistant to hydration. The process is similar to the sintering method to synthesize spinel.

The raw materials mainly use industrial alumina and high-quality light-burned magnesium oxide powder.

Product use: It is widely used in steel smelting,electric furnace roof,ladle, cement rotary kiln, glass industrial furnace and metallurgical industry,etc.It is an ideal material for manufacturing continuous casting

skateboards, nozzle bricks, ladle lining bricks and flat furnace bricks, as well as large-scale cement Basic raw materials for kilns, transition zone lining bricks of medium-sized cement kilns, refractory castables and high and medium temperature kiln furniture bricks.

Fused Spinel Product Process

The company's production of fused aluminum magnesium spinel has many levels, according to the requirementsof users, particle size, fineness can be produced on demand.