Loose-Fill Refractories Alumina Bubble Is Used In The Production Of Lightweight Insulating Refractories

- alumina bubble

- Bubble Alumina

- Hollow ball

Short Description

Alumina Bubble

|

Index Properties |

Type 1 |

Type 2 |

|

|

Chemical composition (%) |

Al2O3 |

99.5min |

99min |

|

SiO2 |

0.5-1.2 |

0.3max |

|

|

Fe2O3 |

0.1max |

0.1max |

|

|

Na2O |

0.4max |

0.4max |

|

|

Packing density (g/cm3) |

0.5-1.0 |

||

|

Damaged rate(%) |

≤10 |

≤10 |

|

|

Refractoriness(°C) |

1800 |

||

|

Particle size |

5-0.2mm, 0.2-1mm,1-3mm,3-5mm, 0.2-0.5mm,1-2mm,2-3mm |

||

|

Test standard |

GB/T3044-89 |

||

|

Packing |

20kg/plastic bag |

||

|

Usage |

Refractories |

||

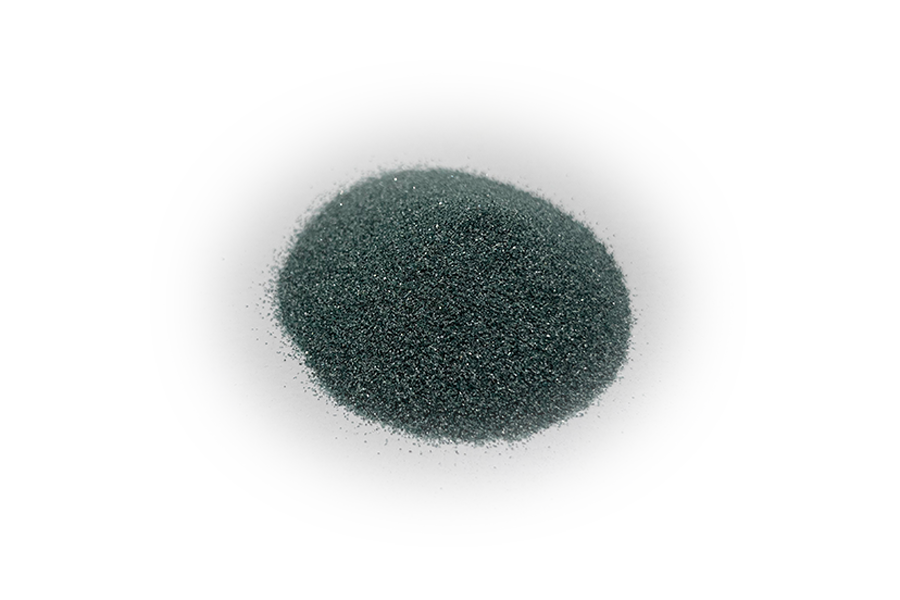

Alumina Bubble is produced by fusing special high purity alumina.Th e melt is atomized with compressed air which leads to the hollow sphere. It is hard but extremely friable with respect to its pressure strengt th. Alumina bubble is used in the production of lightweight insulating refractories where low thermal conductivity and high temperature pro perties are the prime requirements. It is also used effectively for loose-fill refractories.

Alumina Bubble is used in the production of lightweight insulating refr ractories where low thermal conductivity and high temperature properties are the prime requirements as well as for loose fill refractories. It C can be used for sleevesproduction or high insulating ceramic shells for investment casting. It can also be used as a bed in the firing process of vitrified grinding wheels and as a media to filtrate aggressive liquids or melts.

Bubble Alumina is produced from high-purity alumina in an electric arc furnace. Once melted, the alumina is atomized with compressed air, which produces hollow spheres. The melting point of Bubble Alumina is approximately 2100ºC.

Process Of Production And Application

Fused Bubble Alumina is produced by blowing the melt of high purity Bayer process alumina in a controlled atmosphere to produce hollow spheres. Due to its low density and extremely low thermal conductivity fused alumina bubble is ideal for high alumina based Insulating Bricks and castables.