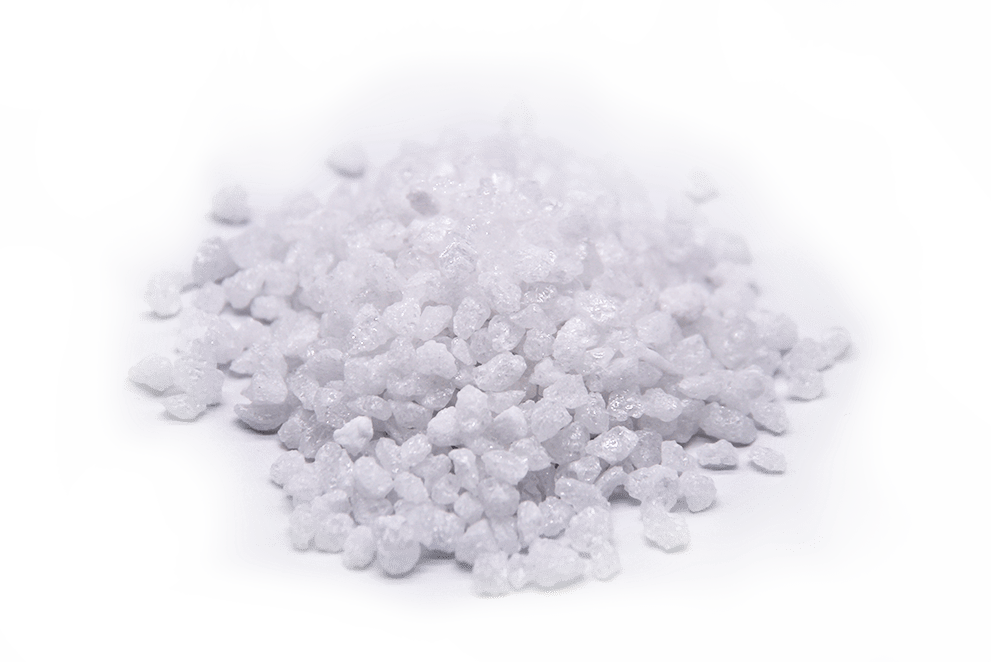

Low Na2o White Fused Alumina,Can Be Used In Refractory , Castables And Abrasives

- White corundum

- White alundum

- WFA

Short Description

Chemical Composition

|

Items |

Unit |

Index | Typical | ||

|

Chemical Composition |

Al2O3 | % | 99.00min | 99.5 | |

| SiO2 | % | 0.20max | 0.08 | ||

| Fe2O3 | % | 0.10max | 0.05 | ||

| Na2O | % | 0.40max | 0.27 | ||

| Refractoriness | ℃ | 1850min | |||

| Bulk density | g/cm3 | 3.50min | |||

| Mohs hardness | --- | 9.00min | |||

| Principal crystalline phase | --- | α-Al2O3 | |||

| Crystal size: | μm | 600-1400 | |||

| True density | 3.90min | ||||

| Knoop hardness | Kg/ mm2 | ||||

| Refractory Grade | Grain | mm | 0-50,0-1, 1-3, 3-5,5-8 | ||

| Mesh | -8+16,-16+30,-30+60,-60+90 | ||||

| Fines | mesh | -100,-200, -325 | |||

| Abrasive&Blasting Grade | FEPA | F12-F220 | |||

| Polishing&Grinding Grade | FEPA | F240-F1200 | |||

White Fused Alumina Variants

| Products/Spec |

Al2O3 |

SiO2 |

Fe2O3 |

Na2O |

| WFA Low Soda Grains and fines |

>99.2 |

<0.2 |

<0.1 |

<0.2 |

| WFA 98 Grains and fines |

>98 |

<0.2 |

<0.2 |

<0.5 |

| WFA98% Demagnetized Fines -200,-325 and -500Mesh |

>98 |

<0.3 |

<0.5 |

<0.8 |

| Items | Size | Chemical Composition (%) | |

| Fe2O3 (min) | Na2O (max) | ||

| WA & WA-P | F4~F80

P12~P80 |

99.10 | 0.35 |

| F90~F150

P100~P150 |

98.10 | 0.4 | |

| F180~F220

P180~P220 |

98.60 | 0.50 | |

| F230~F800

P240~P800 |

98.30 | 0.60 | |

| F1000~F1200

P1000~P1200 |

98.10 | 0.7 | |

| P1500~P2500 | 97.50 | 0.90 | |

| WA-B | F4~F80 | 99.00 | 0.50 |

| F90~F150 | 99.00 | 0.60 | |

| F180~F220 | 98.50 | 0.60 | |

Raw Material And Process Of Production

White Fused Alumina is a high purity, synthetic mineral.

It is manufactured by the fusion of controlled quality pure grade Bayer Alumina in an electric arc furnace at temperatures greater than 2000˚C followed by a slow solidification process.

Strict control over quality of raw materials and fusion parameters ensure products of high purity and high whiteness.

The cooled crude is further crushed, cleaned of magnetic impurities in high intensity magnetic separators and classified into narrow size fractions to suit the end use.

Application

Dedicated lines produce products for different applications.

White Fused Alumina is highly friable and hence used in Vitrified Bonded Abrasives products where cool, fast cutting action is essential and also in the manufacture of high purity Alumina refractories. Other applications include use in Coated Abrasives, Surface treatment, Ceramic Tiles, Anti-Skid Paints, Fluidized Bed Furnaces and Skin / Dental Care.

About Production