Monocrystalline Fused Alumina Is Suitable For Vitrified, Resin-Bonded And Rubber-Bonded Grinding Wheels, Grinding Of Burnable Workpieces And Dry Grinding.

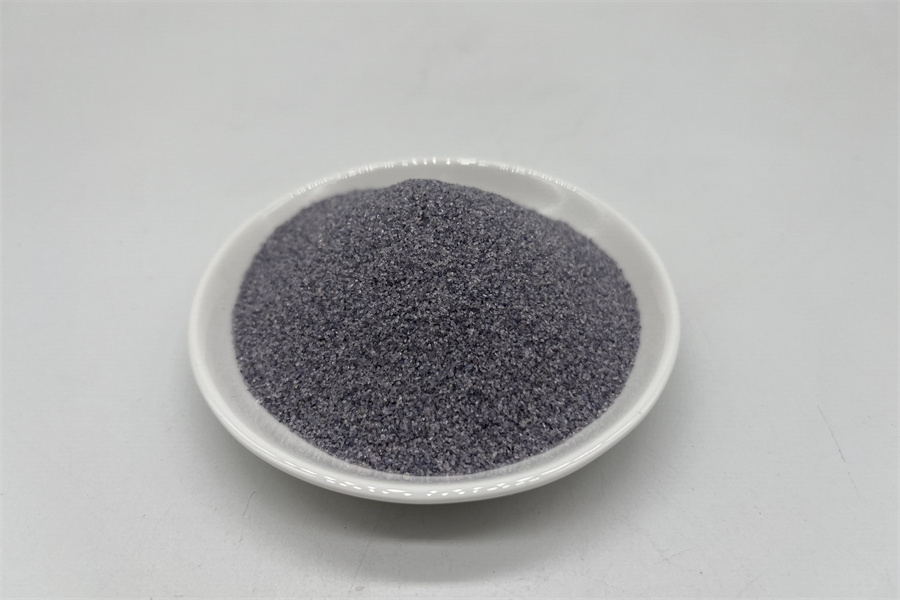

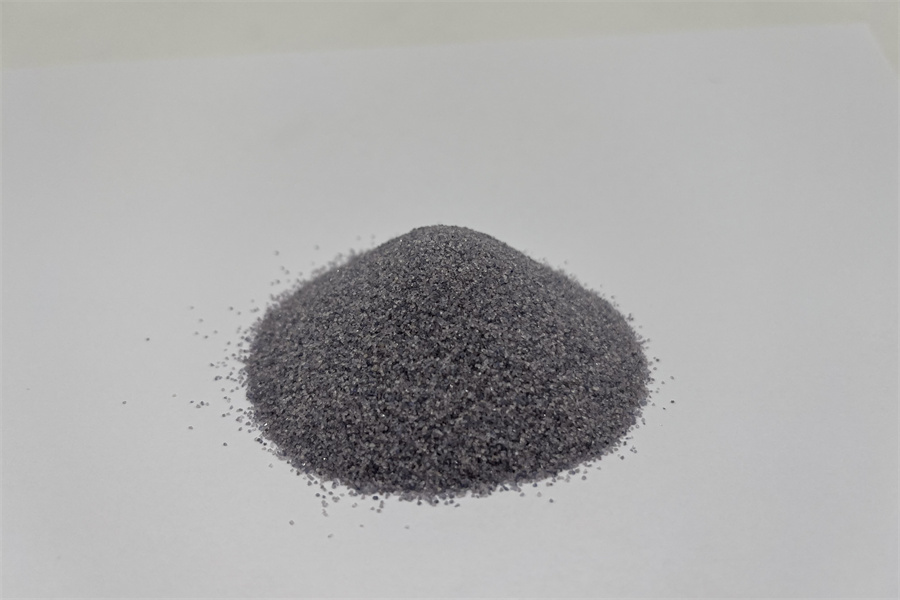

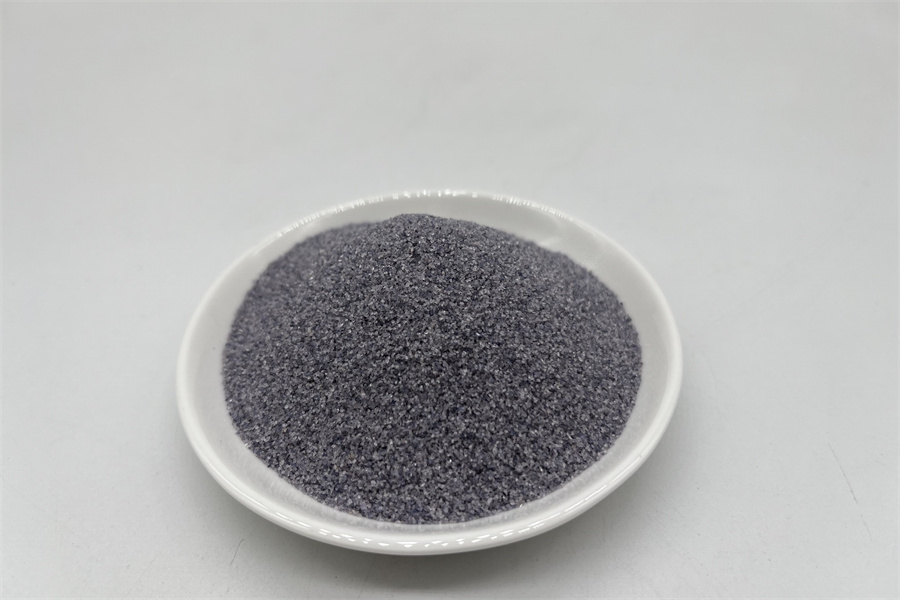

- Monocrystalline Alumina

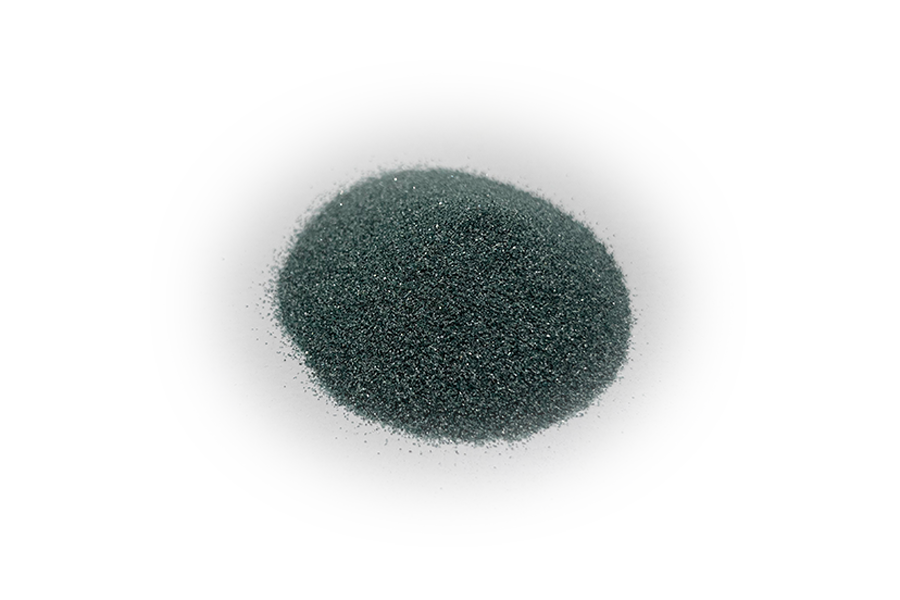

- Single crystal silicon

Short Description

Applications

Monocrystalline Fused Alumina is suitable for vitrified, resin-bonded and rubber-bonded grinding wheels, grinding high vanadium, high-speed steel, austenitic stainless steel, heat-resistant alloy steel and titanium alloy steel, especially for the grinding of burnable workpieces and dry grinding.

|

Items |

Unit |

Index |

Typical |

|

| Chemical Composition | Al2O3 | % | 99.00min | 99.10 |

| SiO2 | % | 0.10max | 0.07 | |

| Fe2O3 | % | 0.08max | 0.05 | |

| TiO2 | % | 0.45max | 0.38 | |

| Compressive Strength | N | 26min | ||

| Toughness | % | 90.5 | ||

| Melting point | ℃ | 2250 | ||

| Refractoriness | ℃ | 1900 | ||

| True density | g/cm3 | 3.95min | ||

| Mohs hardness | --- | 9.00min | ||

| Colour | --- | Grey white/Blue | ||

| Abrasive Grade | FEPA | F12-F220 | ||