Pink Aluminum Oxide Is Sharp And Angular Used In Tool Grinding, Sharpening

- Chrome corundum

- PA

- Chrome Alumina

Short Description

Applications

The FEPA F grades are especially suitable for the manufacturing vitrified bonded abrasives for working hardened steels and alloys with tensile strengths of over 50 kg/mm². It is also used in tool grinding, knife-sharpening applications, precision grinding, profile grinding, flute grinding, tooth grinding, dry grinding of blade segments and mounted wheels.The FEPA P grades are a preferred material for working non-ferrous metals and

| Items/ Chemical Composition |

Unit |

Medium Chrome | Low Chrome | High Chrome | |

| Size:

F12-F80 |

Al2O3 | % | 98.2min | 98.5min | 97.4min |

| Cr2O3 | % | 0.45-1.00 | 0.20-0.45 | 1.00-2.00 | |

| Na2O | % | 0.55max | 0.50max | 0.55max | |

| F90-F150 | Al2O3 | % | 98.20min | 98.50min | 97.00min |

| Cr2O3 | % | 0.45-1.00 | 0.20-0.45 | 1.00-2.00 | |

| Na2O | % | 0.60max | 0.50max | 0.60max | |

| F180-F220 | Al2O3 | % | 97.80min | 98.00min | 96.50min |

| Cr2O3 | % | 0.45-1.00 | 0.20-0.45 | 1.00-2.00 | |

| Na2O | % | 0.70max | 0.60max | 0.70max | |

| Physical Property | Basic Minerals | α— AI2O3 | α— AI2O3 | α— AI2O3 | |

| Crystal size | μm | 600~2000 | 600~2000 | 600~2000 | |

| True density | g/cm3 | ≥3.90 | ≥3.90 | ≥3.90 | |

| Bulk density | g/cm3 | 1.40~1.91 | 1.40~1.91 | 1.40~1.91 | |

| Knoop hardness | g/mm2 | 2200~2300 | 2200~2300 | 2200~2300 | |

Application

1. Pink fused alumina for surface processing: metal oxide layer, carbide black skin, metal or non-metal surface rust removal, such as gravity die-casting mold, rubber mold oxide or free agent removal, ceramic surface black spot, uranium removal, painted rebirth.

2. Pink fused alumina beautification processing: all kinds of gold, gold jewelry, precious metal products of the extinction or fog surface processing, crystal, glass, ripple, acrylic and other non-metallic fog surface processing and can make the surface of the processing into metallic luster.

3. Pink fused alumina for Etching and processing: etching artists of jade, crystal, agate, semi-precious stone, seal, elegant stone, antique, marble tombstone, ceramics, wood, bamboo, etc.

4. Pink fused alumina for Pretreatment: TEFLON, PU, rubber, plastic coating, rubber ROLLER, electroplating, metal spray welding, titanium plating and other pretreatment, so as to increase the surface adhesion.

5. Pink fused alumina for Burr processing: burr removal of bakelite, plastic, zinc, aluminum die-casting products, electronic parts, magnetic cores, etc.

6. Pink fused alumina for stress elimination processing: aerospace, national defense, precision industry parts, rust removal, painting, polishing, such as stress elimination processing.

Process Of Production And Characteristic

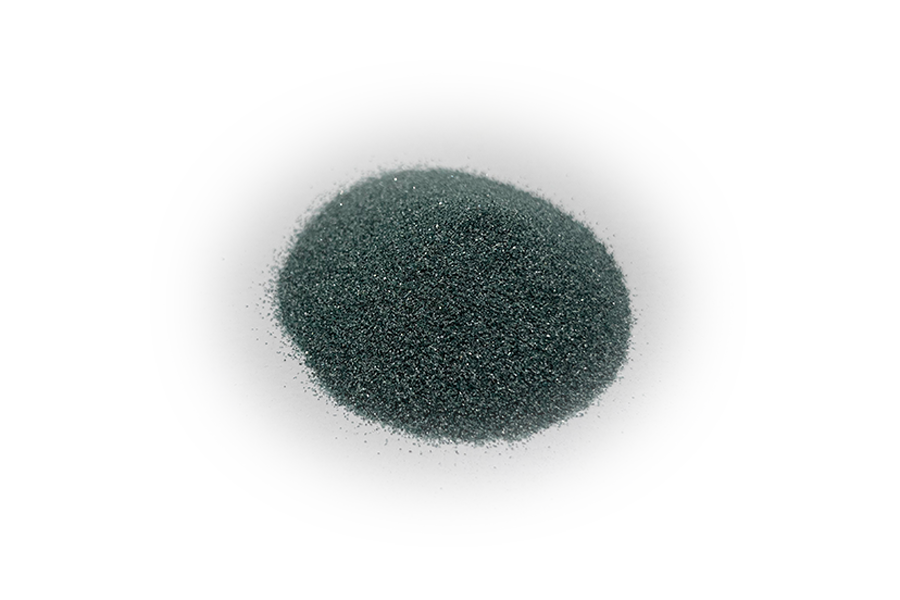

Pink Fused Alumina is produced by doping Chromia into Alumina, which gives the material pink color. The incorporation of the Cr2O3 into the Al2O3 crystal lattice produces a slight increase in toughness and a reduced friability compared with White Fused Alumina.

Compared to Brown Regular Aluminum Oxide the Pink material is harder, more aggressive and has better cutting ability. The grain shape of Pink Aluminum Oxide is sharp and angular.